Have you ever felt limitations while working with your drill press, and if so, what was the reason for your limitations? We’ll show you how to transform your drill press into a powerhouse of precision and convenience, no matter what type of tool you have. The Woodpecker Drill Press Table enables you to remove constraints and gain access to more features.

Discover how a simple addition can revolutionized your woodworking experience: the Woodpecker Drill Press Table is a versatile addition that allows you to work with your drill press on a variety of platforms and with a stable and adjustable base. This comprehensive guide walks you through the entire installation process, ensuring that you get the most out of your device. We’ve got you covered, from choosing the right tools to troubleshooting common issues.

You will learn what are the most important tips for keeping your setup running smoothly as we learn about the installation and maintenance process. The information you learn here will allow you to make the most of your woodworking equipment, whether you are a seasoned woodworker or a newcomer. The Woodpecker Drill Press Table will allow you to maximize the efficiency of your drill press, so let’s get started with the details and make your woodworking game more enjoyable.

Pre-Installation Preparations

In gearing up for the installation of the Woodpecker Drill Press Table, meticulous pre-installation preparations lay the foundation for a seamless and efficient process. The success of any woodworking project hinges on the tools and materials at your disposal, making the first step of gathering necessities paramount.

Gather Necessary Tools and Materials

Navigating through the spectrum of required tools ensures that you embark on the installation journey well-equipped. The arsenal includes, but is not limited to: – **Drill Bits:** Precision is the key, and having a variety of drill bits ensures compatibility with different materials. – **Wrenches and Screwdrivers:** A versatile set to tighten and adjust components with ease. – **Measuring Tape:** Accurate measurements are the linchpin for a precisely installed drill press table. – **Level:** Guaranteeing a flat and even surface for optimal performance.Recommended materials for a smooth installation

Equally significant is the selection of materials to facilitate a smooth installation process. Quality materials not only enhance durability but also contribute to the overall stability of the setup. – **Wood Screws:** Opt for screws that match the material of your drill press table, ensuring a secure fit. – **Wood Glue:** Adding an extra layer of stability, especially for wooden components. – **Cleaning Supplies:** A clean workspace is conducive to precision. Have brushes and cloths to keep the area debris-free.Moving forward to the next frontier of preparations involves setting the stage for the installation process with meticulous workspace setup.

Workspace Setup

Clearing the Workspace

Creating a clutter-free environment is the first step towards a hassle-free installation experience. – **Remove Unnecessary Items:** Clear the workspace of any non-essential tools or materials. – **Organize Tools:** Arrange tools in a way that facilitates easy accessibility during the installation process.Ensuring Adequate Lighting and Ventilation

A well-lit and ventilated workspace is not just a matter of convenience but a strategic move for accuracy and safety. – **Strategic Lighting:** Position lighting sources to eliminate shadows, providing a clear view of the installation area. – **Ventilation Considerations:** Ensure proper airflow to dissipate any fumes generated during the installation, creating a comfortable and safe environment.In essence, the pre-installation phase is akin to tuning an instrument before a performance – meticulous, deliberate, and setting the stage for a harmonious experience. Armed with the right tools, materials, and a thoughtfully organized workspace, you’re poised to embark on the installation journey, ensuring that every turn of the wrench and placement of the table aligns seamlessly with precision and craftsmanship.

Understanding the Woodpecker Drill Press Table

Embarking on the installation journey of a Woodpecker Drill Press Table requires a profound understanding of its intricate components. This section serves as a compass, navigating through the vital elements that constitute the heart of this woodworking enhancement.

Components Overview

1. Tabletop Features

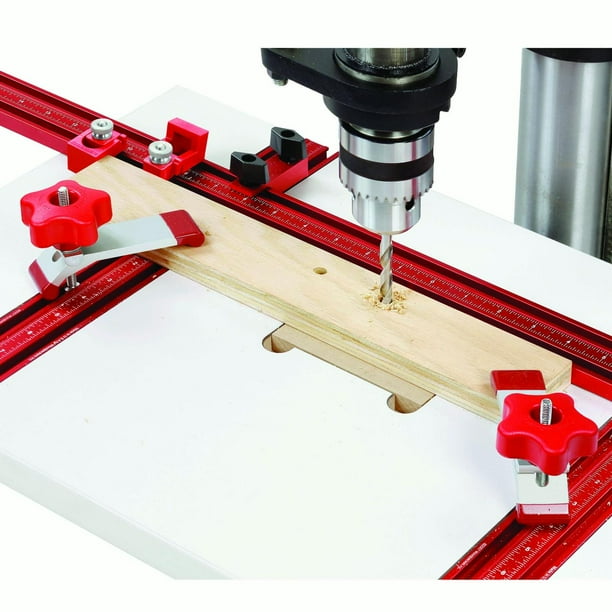

The tabletop of the Woodpecker Drill Press Table stands as the focal point, a canvas for craftsmanship. Key features include: – **Material Selection:** Crafted from high-quality materials, ensuring durability and stability during various woodworking applications. – **Smooth Surface:** Engineered for precision, the smooth surface facilitates seamless movements and accurate drilling. – **Expandable Design:** Many models boast expandable options, providing flexibility for larger projects.2. Fence and T-Track System

Understanding the intricacies of the fence and T-track system is akin to unlocking a treasure trove of possibilities: – **Fence Adjustability:** The fence, a crucial component, offers adjustability to accommodate different workpieces, providing a stable guide for accurate drilling. – **T-Track Precision:** The T-track system embedded in the tabletop allows for the secure placement of accessories, such as hold-down clamps and stops, enhancing overall precision and safety.Reading the Instructions

1. Importance of Following the Manufacturer’s Guidelines

In the realm of woodworking, precision is non-negotiable, and adherence to the manufacturer’s guidelines is the compass that ensures you stay on the right course: – **Optimal Performance:** Following guidelines guarantees optimal performance, preventing potential issues that may arise from improper installation. – **Warranty Compliance:** Many manufacturers tie warranties to proper installation, emphasizing the importance of meticulous adherence.2. Understanding Specific Model Instructions

No two Woodpecker Drill Press Tables are created equal, and understanding the nuances of your specific model is the key to unlocking its full potential: – **Tailored Features:** Each model may come with unique features or specifications, understanding them ensures you leverage the full spectrum of functionalities. – **Avoiding Pitfalls:** Specific model instructions often highlight common pitfalls, empowering users to sidestep potential issues and optimize their woodworking experience.In essence, comprehending the Woodpecker Drill Press Table’s components and instructions is not merely a preliminary step but a strategic move towards elevating your woodworking prowess. From the meticulously designed tabletop to the nuanced instructions guiding installation, every facet contributes to a harmonious symphony of precision and efficiency. So, dive into the specifics, grasp the intricacies, and let the Woodpecker Drill Press Table become an extension of your craftsmanship, unlocking a world where every drill is a masterpiece in the making.

Step-by-Step Installation Process

Embarking on the installation of a Woodpecker Drill Press Table demands a methodical approach, ensuring each step is executed with precision. Let’s delve into the intricacies of the installation process, breaking it down into distinct stages for a seamless woodworking experience.

Attaching the Base

1. Aligning the Drill Press Table with the Drill Press

To initiate the installation, aligning the drill press table with the drill press itself is foundational. This step involves: – **Positioning:** Carefully position the table, ensuring it sits flush with the drill press. – **Alignment Check:** Utilize measuring tools to guarantee accurate alignment for optimal functionality.2. Securing the Base in Place

With alignment perfected, the next crucial step is securing the base, fortifying the foundation for your woodworking endeavors. – **Bolt Tightening:** Utilize appropriate bolts and fasteners to securely attach the drill press table to the drill press. – **Stability Check:** Ensure a stable foundation by testing for any unexpected movement, addressing issues promptly.Installing the Fence

1. Mounting the Fence Securely

The fence plays a pivotal role in guiding and supporting your workpieces during drilling. A secure installation involves: – **Attachment:** Mount the fence firmly to the drill press table, employing recommended screws for a robust connection. – **Alignment Verification:** Validate that the fence runs parallel to the drill bit, preventing any deviation during operations.2. Adjusting the Fence to Desired Specifications

Customization is key, and adjusting the fence to meet your specific project requirements enhances the versatility of your setup. – **Positioning:** Fine-tune the fence position, catering to the dimensions of your workpiece. – **Locking Mechanism:** Utilize any locking mechanisms provided to secure the fence in the desired configuration.Adjusting T-Tracks

1. Ensuring Smooth Movement

The T-track system embedded in the tabletop is a hallmark of versatility, requiring careful adjustment for optimal performance. – **Lubrication:** Ensure smooth movement by applying a suitable lubricant to the T-tracks. – **Testing:** Slide accessories along the T-tracks to verify unhindered movement, addressing any resistance promptly.2. Properly Securing Items in the T-Tracks

Securing workpieces and accessories in the T-tracks demands attention to detail for a secure and efficient workspace. – **Compatible Accessories:** Confirm that accessories are compatible with the T-tracks, ensuring a snug fit. – **Tightening:** Secure items in the T-tracks firmly, preventing any unintended movement during drilling operations.Verifying Stability

1. Checking for Any Wobbling or Instability

Stability is paramount for precision in woodworking, necessitating a thorough assessment for any potential issues. – **Visual Inspection:** Examine the entire setup for signs of wobbling or instability. – **Operational Test:** Conduct a brief test run to detect any unexpected movements during operation.2. Making Necessary Adjustments for Stability

Addressing instability is a proactive measure, ensuring a secure and reliable drill press table setup. – **Tightening Connections:** Recheck and tighten all connections to eliminate wobbling. – **Weight Distribution:** Evaluate the weight distribution on the table and make adjustments as needed.In essence, the step-by-step installation process is a meticulous dance of precision and customization. By aligning, securing, adjusting, and verifying at each stage, you transform your drill press into a woodworking powerhouse, ready to tackle projects with unparalleled accuracy and efficiency. Mastering these installation nuances ensures your Woodpecker Drill Press Table becomes an extension of your craftsmanship, empowering you to create with confidence.

Tips for Maintenance and Troubleshooting

Maintaining the optimal functionality of your Woodpecker Drill Press Table is not merely a task; it’s a commitment to the longevity and precision of your woodworking endeavors. Here, we delve into invaluable tips for both routine maintenance and troubleshooting common issues, ensuring your drill press table remains a stalwart companion in your craft.

Regular Cleaning

1. Removing Sawdust and Debris

Woodworking generates its fair share of sawdust and debris, often settling into the nooks and crannies of your drill press table. Regular cleaning is not just a cosmetic endeavor but a fundamental step towards sustained performance: – **Brush and Vacuum:** Employ a stiff brush and a vacuum to remove sawdust from the tabletop and surrounding areas. – **Compressed Air:** For intricate components, a burst of compressed air proves invaluable in dislodging hard-to-reach particles.2. Lubricating Moving Parts as Recommended

The smooth operation of a drill press table relies on well-lubricated moving parts. Regular lubrication not only prevents wear and tear but also ensures a seamless woodworking experience: – **Manufacturer’s Recommendations:** Refer to the manufacturer’s guidelines for recommended lubricants and intervals. – **Focus on Pivot Points:** Pay special attention to pivot points, adjusting screws, and any areas prone to friction during operation.Troubleshooting Common Issues

1. Identifying and Fixing Misalignments

Misalignments can be the bane of precision in woodworking. Identifying and rectifying these issues is an art that enhances the overall performance of your drill press table: – **Visual Inspection:** Regularly inspect the alignment of the drill press table components, ensuring they are parallel and square. – **Adjustment Procedures:** Refer to the user manual for specific instructions on realigning components, adjusting bolts and screws as necessary.2. Addressing Issues with the T-Track System

The T-track system, while a boon for versatility, can sometimes pose challenges. Troubleshooting T-track issues requires a systematic approach to maintain the functionality of this integral feature: – **Debris Clearance:** Ensure T-tracks are free from debris, preventing obstructions during accessory movement. – **Alignment Verification:** Periodically verify that the T-tracks are parallel to the drill bit, addressing any deviations promptly.In the world of woodworking, where precision is paramount, adherence to a robust maintenance routine and proactive troubleshooting measures becomes the linchpin of success. By routinely cleaning, lubricating, and addressing common issues, you not only prolong the life of your Woodpecker Drill Press Table but also elevate its performance, allowing you to craft with the utmost accuracy and finesse. Remember, a well-maintained tool is a reliable partner in your artistic journey, ensuring that each drill is a testament to the seamless synergy between craftsmanship and technology.

Safety Measures

Ensuring a safe woodworking environment is paramount, and when operating a Woodpecker Drill Press Table, adherence to comprehensive safety measures becomes a non-negotiable aspect of the craft.

Using Personal Protective Equipment

1. Importance of Safety Goggles and Gloves

In the realm of woodworking, where precision meets potential hazards, the significance of donning safety goggles and gloves cannot be overstated: – **Eye Protection:** Safety goggles act as a frontline defense against flying debris, sawdust, and wood chips, safeguarding your eyes from potential injuries during drilling operations. – **Hand Safety:** Wearing sturdy gloves is a proactive measure to shield your hands from splinters, sharp edges, and potential abrasions while handling materials and operating the drill press.2. Ear Protection for Noise Reduction

Woodworking environments often resonate with the hum of machinery, and the constant exposure to noise can pose a threat to your hearing health. Ear protection serves as a shield against the cacophony, reducing the risk of long-term hearing damage: – **Decibel Defense:** Invest in quality ear protection devices, such as earmuffs or earplugs, to mitigate the impact of the drill press’s noise level, preserving your hearing acuity for years to come. – **Consistent Usage:** Incorporate the habit of wearing ear protection consistently during woodworking activities, fostering a safer and more conducive workspace.Understanding Drill Press Safety

1. Safe Operating Procedures

Operating a drill press table demands a nuanced understanding of safe practices to minimize the risk of accidents and injuries. The following guidelines underscore the essence of safe operating procedures: – **Workpiece Stability:** Ensure the workpiece is securely fastened to prevent unexpected movements during drilling, reducing the likelihood of accidents. – **Appropriate Speed and Depth:** Adjust drill press settings according to the material being worked on, striking a balance between speed and depth for optimal results and safety. – **Proper Tool Selection:** Select the appropriate drill bits and accessories, ensuring they match the specifications of the project to avoid mishaps.2. Emergency Shutdown Measures

Preparedness for unforeseen circumstances is a hallmark of responsible woodworking. Familiarizing yourself with emergency shutdown measures ensures a swift and effective response in critical situations: – **Location of Emergency Stop:** Identify and acquaint yourself with the location of the emergency stop button on the drill press, allowing for immediate shutdown in case of emergencies. – **Power Disconnect:** Familiarize yourself with the power disconnect options, such as unplugging the machine or utilizing a circuit breaker, providing an additional layer of safety during emergencies.In essence, safety measures are the bedrock of a productive and secure woodworking environment. The combination of personal protective equipment, adherence to safe operating procedures, and familiarity with emergency shutdown measures creates a framework where craftsmanship thrives without compromising well-being. As you embark on your woodworking journey with the Woodpecker Drill Press Table, let safety be the guiding force that elevates each project, ensuring not only precision in your creations but a steadfast commitment to your own welfare in the workshop.

Main takeaway

As a result, the installation of a Woodpecker Drill Press Table is a game-changer for those of us who are interested in woodworking at all skill levels. By following the detailed steps outlined in this guide, you have effectively improved the capabilities of your drill press, transforming it into a versatile tool for precision and efficiency.

As a result, both the setup and the maintenance must be kept in good order. Using the recommended safety measures and troubleshooting tips, you ensure a smooth and safe woodworking experience. A well-installed drill press table provides a stable platform for a variety of projects, making it an excellent tool for any job.

You can try new things with this improved woodworking setup as you get into your woodworking projects. The Woodpecker Drill Press Table creates an exciting new world of intricate designs and meticulous craftsmanship. Make certain that your workspace is organized, that your equipment is kept in good working order, and that you are reaping the benefits of your newly gained efficiency.

A Woodpecker Drill Press Table is both practical and enjoyable to use in woodworking, where precision is paramount. Simply go ahead and use your drill press to its full potential, and you will be able to craft your next masterpiece. Thank you for sharing your woodworking knowledge with us.

Amhil Khan, a dedicated nature enthusiast and the founder of BirdsOfTheWild.com, is a passionate advocate for the captivating world of avian wonders. With a deep-seated curiosity about the intricate lives of birds, Amhil’s journey began as a fascination and has evolved into a mission to inspire others to appreciate and protect these magnificent creatures.

Amhil’s love for birds led to the creation of Birds of the Wild, a platform where his expertise in ornithology, coupled with his captivating storytelling, provides readers with an immersive and educational experience. Through his lens and words, he captures the essence of birds in their natural habitats, offering a glimpse into their behaviors, migrations, and the ecosystems they inhabit.